Introduction

In the dynamic world of construction and demolition, efficiency, and precision are paramount. Excavators have long been the workhorses of these industries, but their capabilities have taken a giant leap forward with the advent of hydraulic pulverizers. CTHB hydraulic pulverizers are transforming the way we approach tasks like concrete demolition, rock breaking, and secondary reduction of materials. CTHB delves into the fascinating world of excavator hydraulic pulverizers, exploring the design, functionality, and the myriad benefits CTHB excavator pulverizers bring to the construction site.

Understanding CTHB Excavator Hydraulic Pulverizers

CTHB excavator hydraulic pulverizer is a cutting-edge attachment designed to streamline and enhance the demolition process for excavator. Unlike traditional methods that rely on brute force and often lead to collateral damage, hydraulic pulverizers offer a more controlled and precise approach, by mounting on the excavator’s small arm (H-link) and are powered by the hydraulic system of the machine.

Key Components and Design of CTHB excavator pulverizers

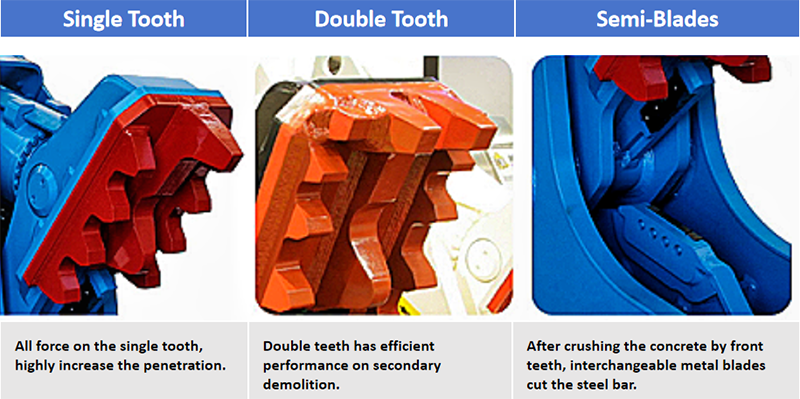

Jaws and Teeth:

At the heart of every hydraulic pulverizers are its jaws and teeth. These robust components are crafted from high-strength and anti-wear steel to withstand the intense forces involved in breaking and crushing materials.

Totals have two jaws on each pulverizer, one is fixed and another one is connect with cylinders by pins. The design of the jaws ensures a firm grip on the material, facilitating efficient processing.

For the teeth, we offer different solutions according to various crushing purpose and cutting purpose. Single tooth, double tooth and semi-blades. For the semi-blades, we use special alloy to produce the blades, improve its cutting ability.

Patent Hydraulic System:

The hydraulic system is the power source of the pulverizer, CTHB design a patent valve to provide the power needed for crushing capabilities.

The excavator hydraulics oil will keep in the valve at first crush, stay at the valve for second crush. This highly shorten the close and open time for concrete crushers, increase the efficiency significantly.

On the valve, operator can adjust the pressure and flow, to control the crushing force and cycle time, for different tasks. This versatility makes CTHB hydraulic pulverizers suitable for a wide range of applications, from demolishing structures to processing concrete and rocks.

Rotating Mechanism:

CTHB hydraulic pulverizers default design has fixed adaptor, we can also feature a rotating mechanism that allows the pulverizer to rotate 360 degrees.

This feature enhances the attachment’s versatility, enabling operators to reach materials from various angles without repositioning the excavator. The ability to rotate also facilitates precise positioning, minimizing the risk of damage to surrounding structures.

Functionality and Applications of CTHB excavator pulverizers

1. Concrete Building Demolition:

Excavator hydraulic pulverizers excel in the demolition of concrete structures. The precise control offered by these attachments allows operators to selectively break down sections of a building without causing unnecessary damage. This is particularly crucial in urban environments where space is limited, and nearby structures must be preserved.

2. Rock / Concrete Pieces Breaking:

When faced with boulders or rock formations, hydraulic pulverizers prove to be formidable tools. Their powerful jaws can break down large rocks into more manageable pieces, simplifying the excavation process. This capability is invaluable in mining, quarrying, and road construction projects.

3. Secondary Reduction:

After the initial demolition or breaking down of materials by hydraulic breakers, hydraulic pulverizers can further process the concrete materials. Whether it’s reducing concrete rubble to a specific size or processing demolished materials for recycling; also can help recycle the steel bar in the concrete building.

Advantages of Applying CTHB Excavator Hydraulic Pulverizers in Construction Site

1. Easy Mouting & Operating:

Operators easily connect the pipes (the black pipes connect hydraulic breaker line and CTHB hydraulic ulverizer [shown in the following picture]) on the hydraulic breaker line on the excavator. When you order the pulverizers, the pipes and foot pedal valve is included. If there is no hydraulic breaker line on the excavators, we can also supply the accessories by telling the excavator brand and model.

Step on the foot pedal, one direction is closing the jaw, step on another direction will open the jaws.

2. Versatility:

The versatility of hydraulic pulverizers is a game-changer. With the ability to rotate 360 degrees, these attachments can tackle tasks from various angles without the need for constant repositioning. This adaptability makes them suitable for a wide range of applications, from demolishing buildings to processing materials for recycling.

3. Time and Cost Savings:

The efficiency of hydraulic pulverizers translates to significant time and cost savings on construction sites. Tasks that once required manual labor or less precise machinery can now be completed quickly and with minimal effort. This increased efficiency contributes to overall project timelines and budget management.

4. Reduced Environmental Impact:

CTHB pulverizers contribute to sustainable construction practices by promoting the recycling of waste. By processing debris for reuse, it helps reduce the environmental impact associated with transporting and disposing of construction and demolition waste.

Conclusion

CTHB Excavator hydraulic pulverizers have ushered in a new era of efficiency, precision, and versatility in the construction and demolition industries.

The ability to break down concrete materials with makes pulverizer indispensable tools when working in construction sites. As technology continues to advance, we will keep refine our pulverizers. What we think, the excavator hydraulic pulverizer is not just a tool, it’s a symbol of progress and a testament to our commitment to smarter, more sustainable construction practices.

-Hydraulic-Breaker.jpg)